How is your salt made?

Whether you love Maldon’s sea salt or the famous Himalayan rock salt, I always ask friends, family, or customers two simple questions – ‘do you know how it is made?’ and ‘where does your salt come from?’. The vast majority of the time, the answer is ‘I don’t know’…or ‘I don’t care’ but I try to ignore that one. With the growth of the organic movement and agricultural traceability, it is more important than ever to know how and where your food is being produced. Salt is an essential mineral for your body’s vital functions, particularly your nervous system. In the early days, salt was used as currency, which shows the importance of this mineral. So, do you know how your salt is made?

Salt production has undergone various transformations, from crude methods to modern technological advances. I am going to try help you out with the ‘how’. In simple terms, there are different salt extraction systems:

- Solar salt production

- Sea water or Salt Lake

- Rock salt mining

- Rock Salt (E.G. Himalayan)

- Table Salt

- Thermal vacuum evaporation

- Sea water

- Salt brine

Also, ion exchange, desalination and electrolysis but the outputs are pretty small so we will focus on the three mains ones above.

Solar evaporation

This is the oldest and most popular method of salt production. It seems like a simple process, but it requires a lot of patience and planning. There are various different solar evaporation techniques, but I will explain how we produce sea salt because it would be a bit pointless not to.

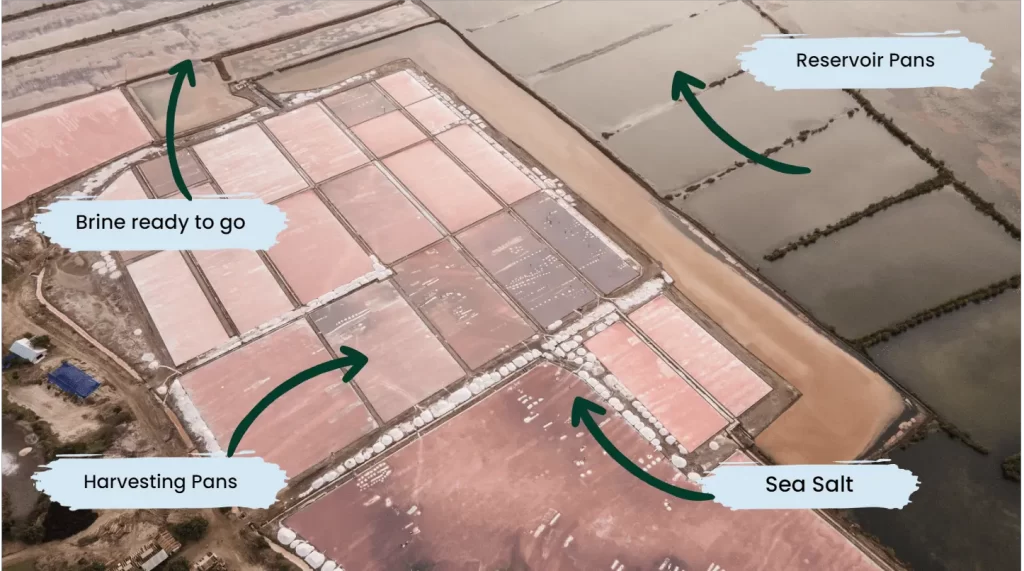

It is a simple process that involves the use of sun and wind to evaporate sea water to produce salt. Seawater is pumped into interconnected and gravity-fed reservoir pans enabling the seawater to turn into brine through solar and wind evaporation. The brine is pumped into shallow interconnected crystalliser ponds to allow the brine to flow from one pond to another as it gradually evaporates.

Further evaporation allows the salt to precipitate from the brine forming a salt crust on the floor of the crystalliser pond. The salt is then harvested and placed into small heaps outside the pond to air dry. After this, it really depends on the producer as there are many ways to process the salt.

Salt Mining

Salt mining is the extraction of mineral salt (commonly referred to as rock salt) from underground salt formations. Ancient sea salt deposits undergo immense metamorphic pressures to compress the sea salt into rock salt. It is a non-renewable form of salt so there is a limit to how much we can have. Quarrying or deep-shaft mining are the primary techniques to extract rock salt using various methods, such as blasting, cutting, or using specialized machinery. The extracted salt is usually coarse and usually contains other mineral impurities causing discolouration.

Most rock salt is used for industrial purposes and a small proportion is refined to produce table salt. The most famous of these rock salts is the Himalayan rock salt which has taken the world by storm. The pink colour is due the effect of trace mineral impurities, such as iron, zinc, manganese and potassium, during the metamorphic process. The salt is crushed and sorted to reduce impurities. There are unsupported health claims that about Himalayan rock salt offers having significant health benefits due to these trace minerals. Sadly, you would have to consume tons a large amount of Himalayan rock salt for this to have any noticeable effect! to have any effect of those minerals.

Thermal vacuum system

This is a common method of sea salt production in the absence of natural sunshine and wind, generally in colder climates, is replaced with modern machinery and energy. I don’t have a great deal of experience in this production process, and I am sure that each site has a different and unique method. However, the description of this method is based on my site visits and research.

- Extraction of seawater or brine: Seawater or brine is extracted from saltwater sources such as oceans, seas, lakes or underground deposits.

- Pre-treatment of the seawater or brine: The seawater or brine is pre-treated to remove impurities such as sand, clay, and other suspended solids. This is done to prevent these impurities from fouling the evaporation equipment.

- Concentration of the seawater or brine: The seawater or brine is then concentrated by removing the water content. This is done by using a series of vacuum evaporators. As the water is removed, the concentration of salt in the remaining brine increases.

- Crystallisation: Once the concentration of salt in the brine is high enough, the brine is transferred to a crystallization tank. The salt then crystallizes out of the brine, forming a layer of salt crystals on the bottom of the tank.

- Harvesting and drying: The salt crystals are then harvested and washed to remove any residual impurities. The salt is then vacuum dried to remove any remaining moisture.

Much of the perfect salt flakes are produced in this controlled production environment. This process is a feat of engineering but does require continuous usage of large amounts of energy throughout the year. There are higher sodium sulphate concentrations and lower calcium and magnesium mineral content in comparison to the solar evaporation system (Sedivy, 2009).

One final point, I am not an academic or production expert but love everything to do with salt and have grown up in a salty family so these are my findings from my first-hand experience and online research. As my friends have found out, I love the topic of salt a bit too much so if you ever bump into me, I apologise in advance.

P.S. Did you know…

I want to also highlight two really unique production techniques that I have come across.

Blackthorn salt in Scotland, UK uses a trickling technique through a large blackthorn tower to produce their brine. It adds a distinctive taste to their salt that is incredible!

Tasman Salt in Tasmania, Australia mixes both solar and thermal production processes together. They have a very clever, sustainable technique of using solar piping to create their brine. Their aim of using clean technologies is inspirational.

Saltverk in Reykjanes, Iceland uses geothermal energy from the hot springs to pre-heat, boil, and dry their salt. It is a great use of the earth’s natural resources to create amazing salt. I really want to try their artic thyme and lava salt so saltverk if you are reading this – let’s do a swap?